When evaluating cylinder repair versus replacement, you need to consider some simple but valuable information. It really comes down to three basic considerations to benchmark:

- Cost and availability of a new cylinder

- Cost and time to repair the cylinder

- Downtime costs

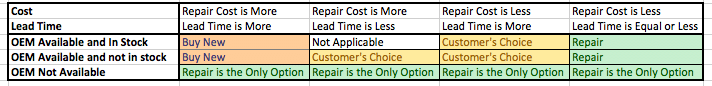

I have created a simple matrix for you using the criteria:

You can see that, of the 12 scenarios in the matrix, over 50% lean towards repair! A re-manufactured cylinder will most often cost less than a new cylinder, and if the work is performed in a time-effective manner by a reputable company, repair will probably be your best option.

The question I am most often asked is:

“Can WHECO repair my damaged cylinder?” Yes we can! In fact, WHECO provides cylinder repair and re-manufacturing not only for cranes and other construction equipment, but also for industrial applications. WHECO has the capability to perform large and small bore, long and short stroke, and standard and metric repairs. Our cylinder shop is fully integrated with our own machine shop, fabrication capabilities, and includes an 80′ cylinder assembly, disassembly, and testing table.

If you would like more information about our cylinder repair capabilities, please click here. You can also submit a request for proposal, and we will provide you with a prompt reply. You can also simply call me or anyone at WHECO anytime.

I am confident that these tips, and the matrix, will help you when considering whether to repair or replace a hydraulic cylinder.

Thank you for your consideration.

If you liked this post, check out some of WHECO’s other work:

WHECO Repairs Bauer BG18 Mast for Malcolm Drilling