This Post Comes from one of WHECO’s newest team members, Greg Etue

Since joining WHECO Corporation this past October, the number-one question I get from customers is: Do I need the approval of the original equipment manufacturer (OEM) before making structural repairs to my own cranes?

Since joining WHECO Corporation this past October, the number-one question I get from customers is: Do I need the approval of the original equipment manufacturer (OEM) before making structural repairs to my own cranes?

Having worked for many years in retail crane distribution, I was always told by the manufacturer that when it came to boom and structural repairs, they always had the last word on whether you can repair or if you must replace damaged equipment and components. When I met WHECO Corporation, I found this was not the case.

Most OEMs do not have the means, facilities, or desire to accommodate structural repairs. And their policies generally prohibit or at least discourage repair. The obvious reason is that they don’t want anything to interfere with their lucrative aftermarket parts business. These policies would appear to leave customers with no option except to replace the damaged parts and components or, in the worst-case scenario, take the crane out of service. The OEMs are also known to aggressively defend their policies through threatening letters and/or threats of refusal to sell parts and components.

So what can you do about it?

Defend your right to have your crane repaired. While it is very important to know that OSHA standards and regulations do require that repairs or adjustments of equipment must meet the manufacturers’ criteria, it is equally important to know that OSHA provides an avenue for non-OEMs to provide repairs and adjustments by using the services of a registered professional engineer to develop the criteria. In other words, regardless of OEM policy, OSHA allows you to keep the repair option on the table.

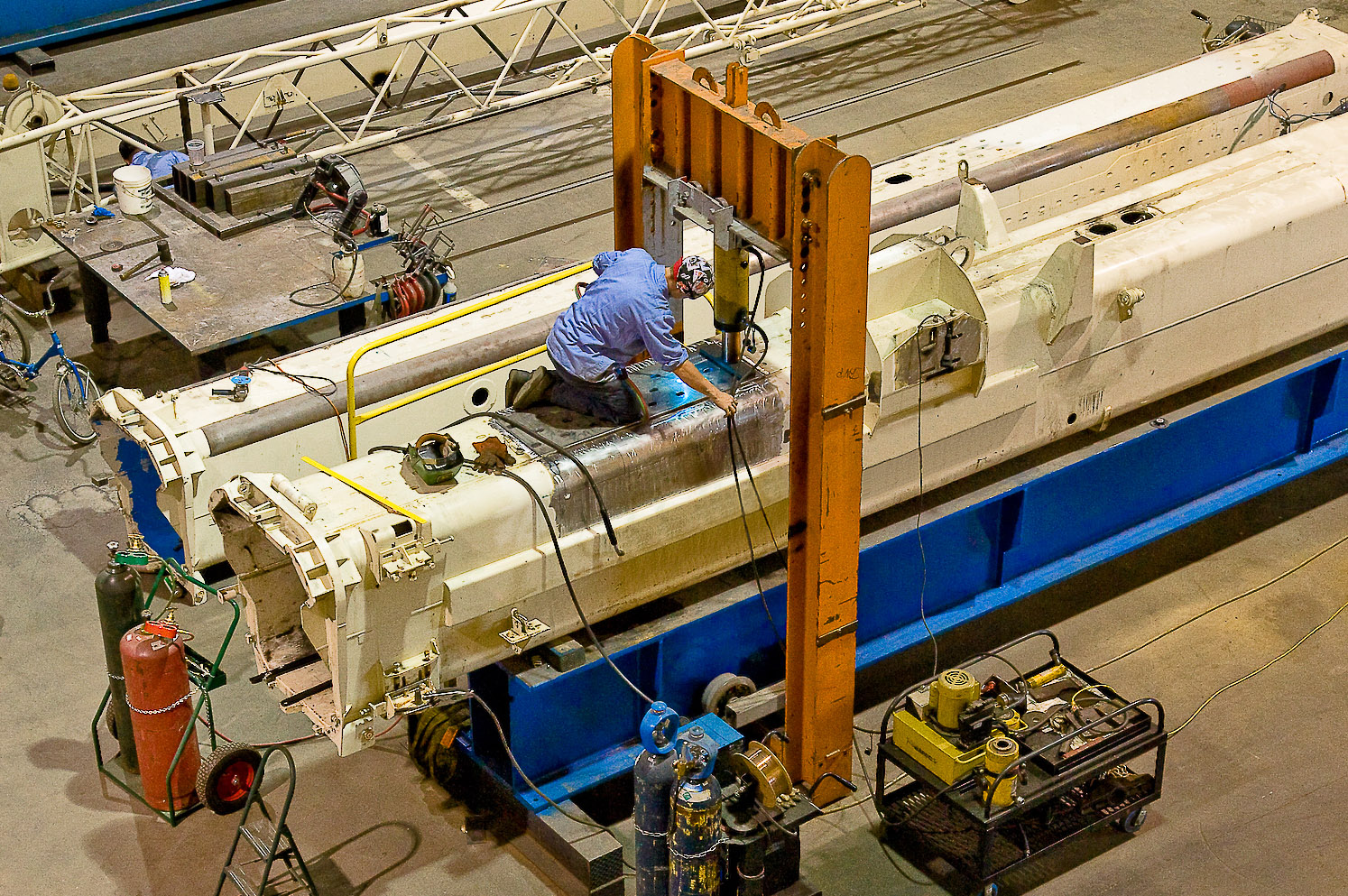

Learn the facts and understand the truth about structural crane repairs. It is possible to safely engineer repairs and rebuild everything from minor damage to more complex lattice and hydraulic boom and frame and superstructure structural repairs. An engineered repair will generally provide the most expeditious and economic solution to an otherwise expensive replacement option.

The work performed at WHECO Corporation is all engineered, tested, certified, guaranteed, warranted, and fully documented. All repairs meet or exceed all OSHA, Cal-OSHA, ANSI, and AWS standards, and are fully compliant. WHECO operates six repair facilities located in Richland, WA; Aiken, SC; Houston, TX; Seattle, WA; Santa Fe Springs, CA; and Kwajalein Atoll in the Marshall Islands.

Please take some time to look around our website and visit our blog. You are also welcome to give me a call.

Hope you find this document useful and informative. – Greg Etue, National Sales Representative (678) 764-782